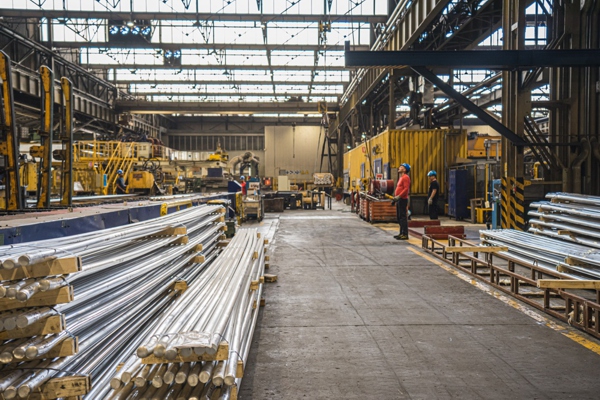

Products

The possible applications of extruded aluminum allow us to meet the diverse needs of our customers. The technical staff makes its know-how available to contribute to the best feasibility of the product, thus responding to the needs of the market.

All non-standard inquiries, not included in the product range, are subject to a feasibility study by our technical department.

STANDARD BARS

-

Round bars from 30 mm to 320 mm

-

Square bars from 30 to 220 mm

-

Flat bars With a minimum thickness of 30 mm and a maximum width of 400 mm

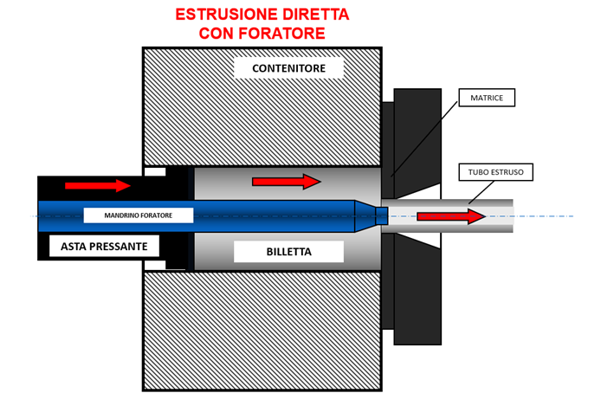

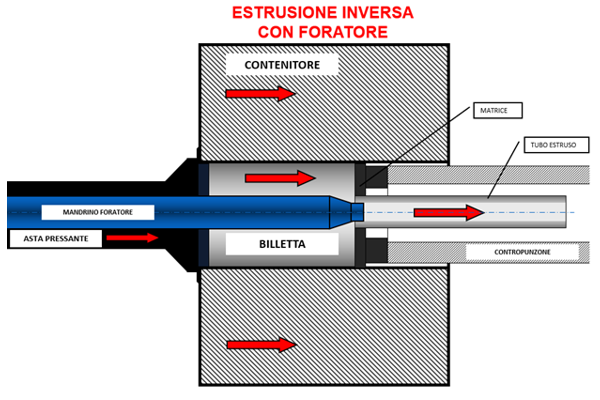

TUBES WITH PRESSING STEM

-

Tubes with pressing stem with an outside diameter between 70 mm and 290 mm

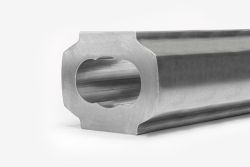

DRAWING PROFILES

-

We offer and produce profiles according to customer drawings.

PUMP BODIES

-

Pump bodies 0.5 - 4.5 groups